Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

KYHE TECH

Your One-Stop Partner for Low-Cost, High-Performance Titanium Alloy Powder & Rapid Trial Production.

Utilizing revolutionary DH-S™ technology, powder costs are reduced by 2/3, and production cycles are shortened by 60%-90%.

Why Partner with KYHE TECH?

Leveraging our proprietary DH-S® technology and Global Recycled Standard certified eco-friendly processes, we deliver superior titanium alloy powders and MIM parts at significantly reduced costs, empowering your innovation.

Significant Cost Reduction

Our DH-S® technology slashes powder costs to near stainless steel levels, reducing overall production expenses by 50-90%.

Superior Performance

Achieve mechanical properties exceeding ASTM/ISO standards, including tensile strength >950MPa and excellent corrosion resistance.

Eco-Friendly & GRS Certified

As the world's first Global Recycled Standard certified titanium alloy enterprise, we champion sustainable, low-carbon manufacturing with >95% material recycling.

One-Stop Solution

From proprietary powder development to precision MIM parts and small-batch trials, we offer a complete, integrated service.

High-purity, near-spherical DH-S® powder with excellent flowability, ideal for 3D Printing, MIM, and PM. Benefit from significantly lower costs and superior performance. Annual output 80T+ (expandable).

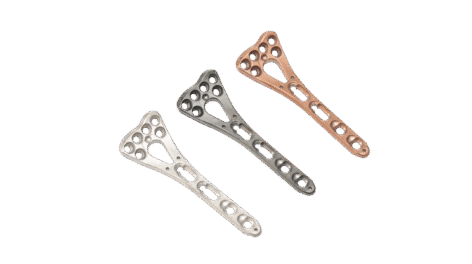

Leverage our MIM expertise for complex, high-precision titanium parts (±20µm accuracy, 1 million pcs/month capacity). Need rapid prototyping? Our indirect 3D printing offers samples in as fast as 7 days.

Beyond powder and MIM components, we deliver fully finished and assembled titanium alloy products. From consumer goods to industrial parts, benefit from our one-stop manufacturing capabilities and GRS certified recycled materials.

Why Choose Us

Driven by Innovation, Built on Expertise

Explore the core strengths that set us apart and deliver unparalleled value in titanium alloy manufacturing.

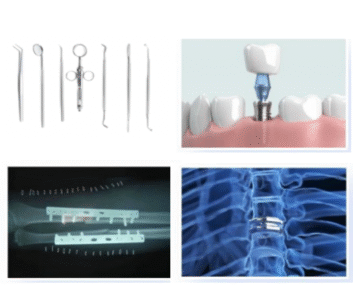

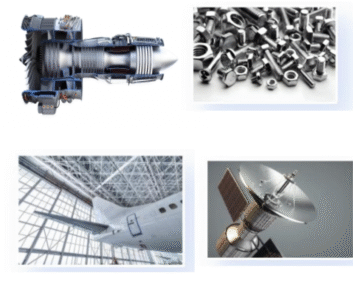

Explore real-world examples of how our versatile and cost-efficient titanium alloy powders and finished products are actively transforming diverse industries. We provide robust, high-performance solutions tailored to your specific application needs, driving innovation and market success.

Medical-Surgical instruments, dental implants, orthopedic trauma & joint implants.

AerospaceE- engine components, aircraft parts, satellite components, fasteners.

Consumer Goods-Golf heads, fishing tackle, creative products, badminton rackets, smart wearables.

AerospaceE- engine components, aircraft parts, satellite components, fasteners.